How to Make Animatronic Dinosaur Model

Animatronic Dinosaur Model

Simulation dinosaur is the use of modern technology to create realistic dinosaurs based on computer-restored pictures of dinosaur fossils. The appearance, shape and movement of the restored simulated dinosaurs are very realistic, lifelike in shape and lifelike in movement.

The simulated dinosaur can be more intuitive and visually let people understand the dinosaur and restore the style of the ancient dinosaur era. Simulated dinosaurs can let children directly understand dinosaurs

Next, let me introduce to you the specific production process of the simulated dinosaur model:

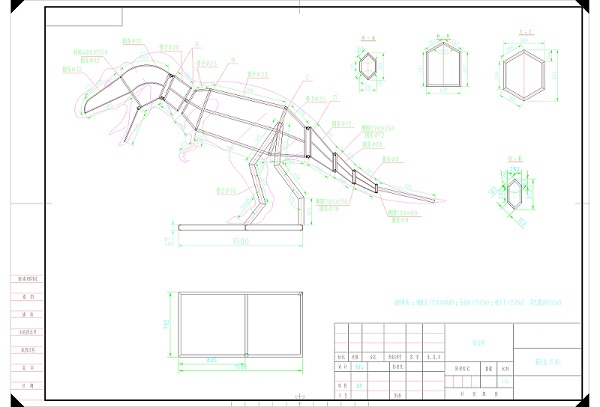

1. CAD drawings

simulation dinosaur

CAD steel frame design, including the type of steel material used, the type of cylinder or motor used, the design of the installation position, and the point design of the transmission.

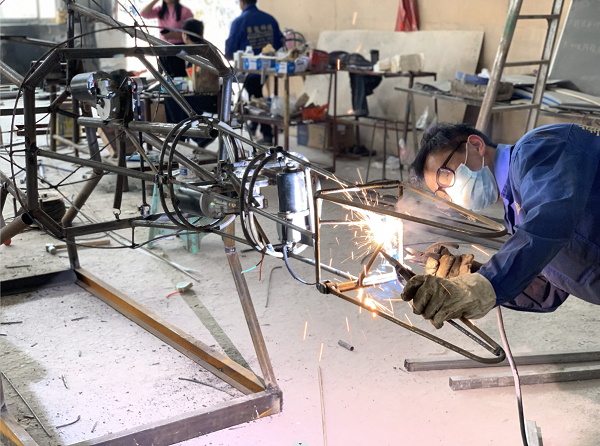

2. Steel frame production

zigong dinosaur model manufacture

For the production of the steel frame, the action test is performed for 2 hours after the steel frame is completed. After the test is completed and passed, the whole steel frame is painted with anti-rust paint. After the anti-rust paint is completely dry, it is handed over to the next process.

3. Product shape

customized simulation dinosaur

Product modeling, sticking sponge (ordinary sponge, fireproof sponge) on the outside of the steel frame, and then the art technicians will shape the product according to the pictures provided by the customer.

4. Surface skin texture treatment

customized dinosaur model

For skin production, use soldering irons of different specifications to iron out different textures of different depths and sizes on the surface of the sponge. After the texture is processed, stick stockings on the surface. After the stockings are glued as a whole, brush the surface of the product with a silicone pot liquid, and wait for the liquid to dry completely. Repeat the brushing 3 times, the product skin is finished

5. Coloring

dinosaur model

Product coloring, after the skin treatment is completed, the product needs to go through a 24-hour action test, and the product that passes the test can be colored. The coloring technician will choose different types of coloring materials according to different materials, such as: Oil paints, acrylic colors, car paints, etc.

Post time: Feb-16-2023